The Importance of Proper Installation of Self-Drilling Roofing Screws

Correct installation of self-drilling (farmer) screws is crucial for the durability and watertightness of the connection between the roofing sheet and the roof structure. Improper installation may lead to leaks, water ingress, and accelerated wear of roofing components.

The Role of Self-Drilling Screws in Roof Construction

Self-drilling screws are specifically designed for fastening tile-effect sheets, trapezoidal sheets, and metal roofing panels to wooden substructures. Their design provides:

-

Mounting stability – the thread and integrated drill tip allow for quick installation and secure anchoring in wood.

-

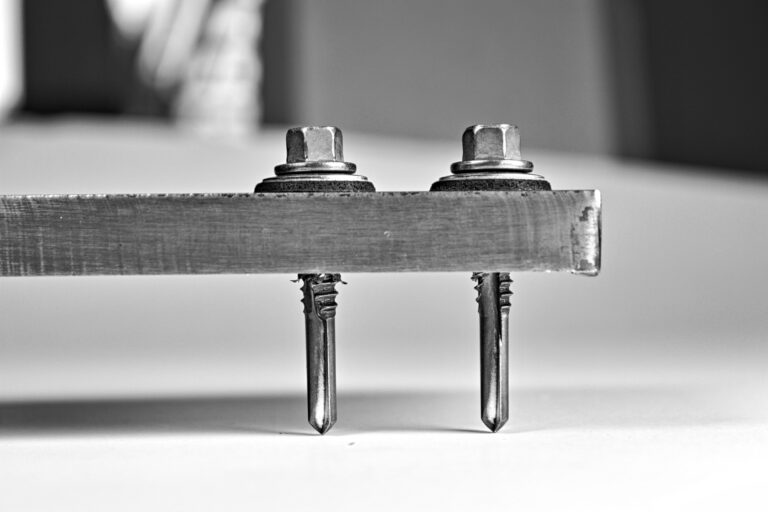

Watertight connection – the EPDM washer under the screw head protects the fastening point against water and moisture.

-

Corrosion resistance – special protective coatings prevent rust and ensure reliable performance in harsh weather conditions.

Impact of Proper Installation on Roof Tightness

To ensure optimal waterproofing, it is essential to follow the manufacturer’s instructions and adhere to the following key guidelines:

-

Proper screw length selection – the screws must be long enough to ensure secure anchoring in the wooden substructure.

-

Correct placement of screws – screws should be inserted at the highest point of the tile sheet wave, not in the lower groove, to avoid water accumulation around the fastener.

-

Appropriate tightening – screws should not be over-tightened (which may deform the washer and reduce its effectiveness) or too loose (which may cause leaks and loosening over time).

-

Avoid overheating during installation – drilling at high speeds can damage the protective coating on both the sheet and the screw, accelerating corrosion.

Consequences of Installation Errors

Improper installation of self-drilling screws can lead to serious issues, such as:

-

Water leaks – a poorly seated or damaged washer cannot protect against moisture penetration.

-

Corrosion of screws and sheets – if the protective coating is damaged, rust can form, weakening the roof structure.

-

Loose fastenings – under-tightened screws may loosen over time, leading to noise and reduced stability of the roofing.

-

Sheet detachment during strong winds – incorrectly fastened sheets are more susceptible to wind uplift, endangering the entire structure.

Proper Installation Techniques Ensure Long-Lasting Roof Performance

Using the correct installation methods, ensuring proper tightening, and selecting high-quality screws will guarantee safety, longevity, and an aesthetically pleasing roof for many years.

How to Select the Right Screws?

There are three key factors that affect proper screw selection:

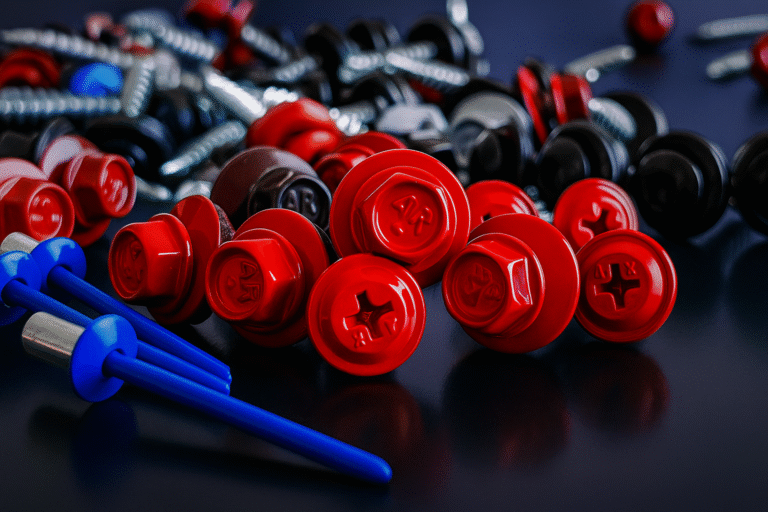

1. Type of Screw

Should be selected based on:

-

the type of structural substrate

-

the required load-bearing capacity specified in the project

-

the minimum and maximum substrate thickness

2. Thickness of Fastened Components

-

type and thickness of the substrate

-

thickness of the elements being fastened

For sandwich panels:

-

thickness of the sandwich panel at the mounting point

-

thickness of caps and sealing tapes

3. Corrosion Resistance

Choosing the right fasteners is essential for the durability and safety of the structure, especially in corrosion-prone environments.

Selecting corrosion-resistant fasteners improves the lifespan and reliability of the connection and reduces the risk of damage due to material degradation. It is advisable to follow standards and manufacturer recommendations to ensure long-term performance.