Coating of Farmer Screws – Durability, Aesthetics, and Corrosion Protection

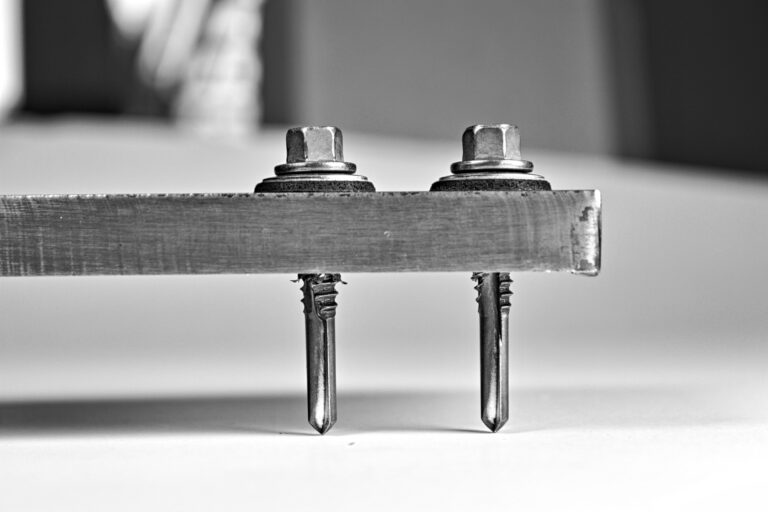

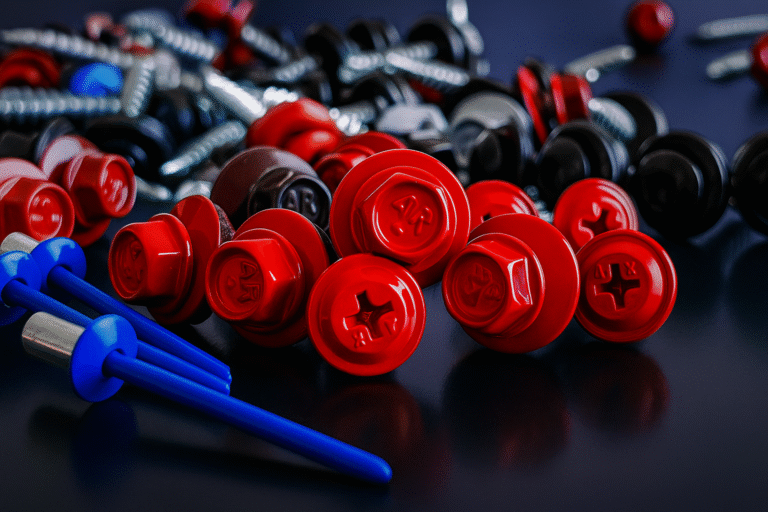

Farmer screws used for mounting metal roof tiles are exposed to intense atmospheric conditions. Therefore, it is crucial that they have a durable and resistant coating that not only enhances their appearance but, most importantly, protects them from corrosion. In our production, we focus on quality – that’s why we carry out the screw painting process exclusively in-house, using advanced powder coating lines and powder paints from leading manufacturers. This gives us full control over the coating quality and allows us to guarantee resistance to moisture, UV radiation, and changing weather conditions.

What Differentiates the Coatings?

There are two main methods of applying protective coatings: powder coating and wet painting. Both methods impact the durability and resistance of the screws to environmental factors.

It’s important to note that if the screws are intended for outdoor use in areas exposed to rain, snow, and UV radiation, powder coating is definitely the better choice due to its greater durability and corrosion resistance.

Powder Coating

This involves applying electrostatically charged powder particles to the screw’s surface.

The screw is then cured in an oven at a temperature of around 160–200°C, which causes the powder to melt and form a durable coating. Powder coating provides superior anti-corrosion protection due to its thick and uniform layer, significantly extending the screw’s lifespan, especially in humid and harsh weather conditions.

Advantages:

-

High corrosion resistance – a thick, sealed layer of paint effectively protects against moisture and salt.

-

Excellent mechanical durability – the coating is more resistant to impact and abrasion than wet paint.

-

No dripping – thanks to electrostatic application, the paint does not run or form streaks.

-

Eco-friendly – solvent-free, reducing the emission of harmful substances.

Wet Painting

This method involves spraying liquid paint using a spray gun.

After application, the paint dries at room temperature or in an oven, forming a thin protective layer that is more susceptible to abrasion, mechanical damage, or chipping. It offers lower corrosion resistance compared to powder coating, and the use of solvents makes it less environmentally friendly.

Why is Powder Coating the Best Choice?

If you plan to use Info-GLOBAL Fastening® colored screws on a roof, façade, or for mounting steel structures and sandwich panels, powder coating is the best solution so far. Thanks to increased resistance to rain, snow, frost, and UV radiation, our powder-coated screws are the top choice.