How are Info-GLOBAL Fastening®

screws made?

Our approach to innovation

Due to excellent corrosion protection, even under maximum loads and high temperatures, special coatings are primarily used in the automotive and marine industries.

Building on the experience of these sectors and meeting the expectations of the most demanding customers, we have introduced the EsC™ (Ecological Suppressor of Corrosion) coating, which is used to protect our products.

Coatings

Innovative

ESC™ coating

Thanks to its excellent corrosion-resistant properties, even under extreme load conditions and high temperatures, innovative special coatings are primarily used in the automotive and marine industries. Drawing from the experiences of these sectors and responding to the needs of the most demanding customers, we have developed the EsC™ coating (Ecological Suppressor of Corrosion), which effectively protects our products.

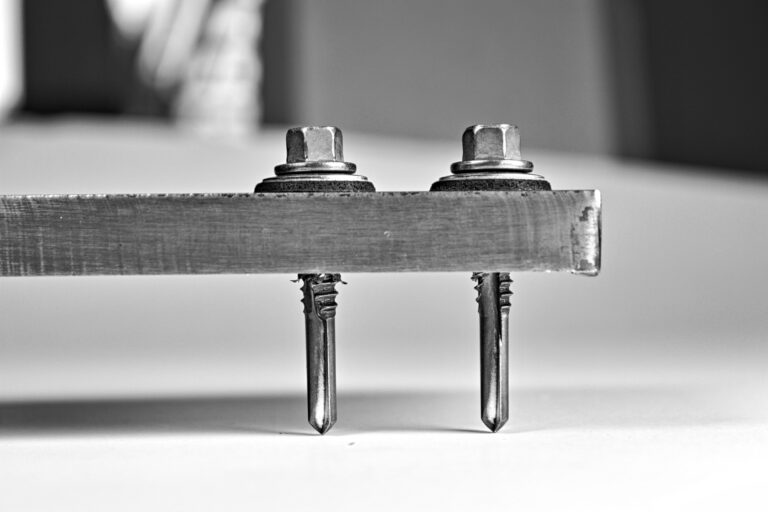

Screws exposed to aggressive environments require exceptional corrosion protection, which is provided by the EsC™ coating.

Moreover, the hexavalent chromium-free formula ensures that all our products coated with EsC™ are safe to use, especially in industries where environmental protection requirements are particularly important.

Key Features of the EsC™ Coating

1. Superior corrosion protection – even under high temperatures and heavy loads, particularly in harsh environments that require specialized protection.

2. Elimination of galvanic corrosion – prevents contact corrosion when used with materials such as aluminum.

3. Durability – long-lasting protection against corrosion-related damage, enhancing the longevity and reliability of protected components.

4. Versatility – suitable for a wide range of product types.

5. Certified performance – all products coated with EsC™ undergo salt spray testing according to PN-EN ISO 9227:2007 – withstanding over 1000 hours without red rust.

Eco-GrePert™

ceramic coating

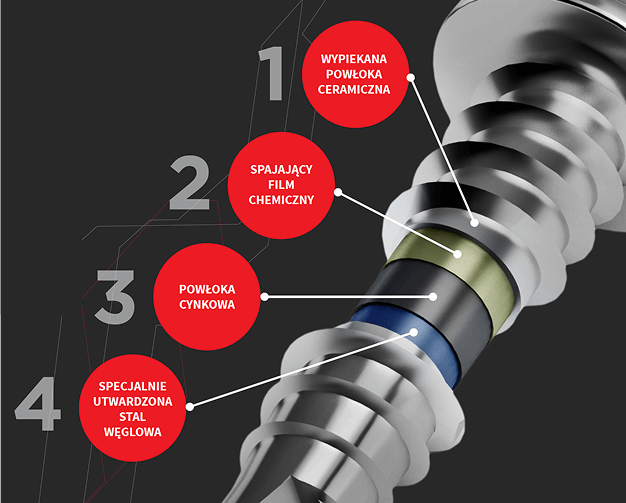

Eco-GrePert™ is an advanced, inorganic, triple-layer ceramic coating developed to deliver maximum resistance to harsh environmental conditions that may lead to corrosion.

This innovative protective layer consists of a baked ceramic coating, a chemically bonded sealing film, and a zinc layer on specially hardened steel. Together, they create a highly durable barrier against external factors such as high temperatures and moisture.

The structure of the Eco-Grepert™ coating is the ideal solution for industries that require long-term protection of metal components.

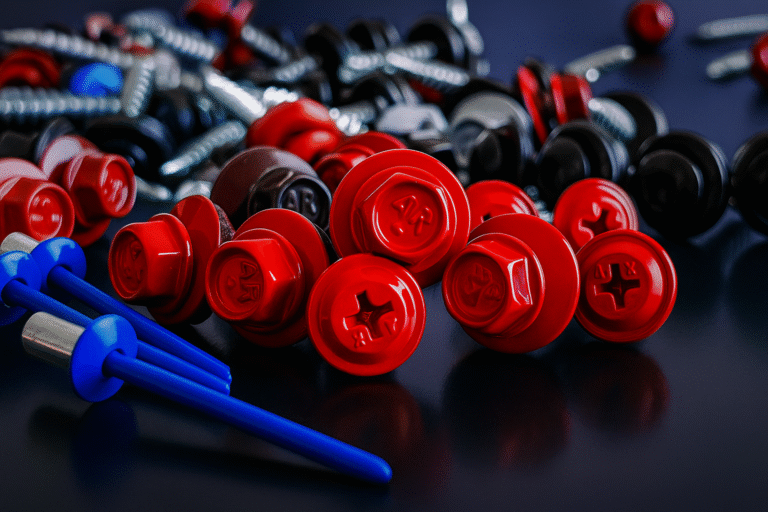

Powder paint

coating

Thanks to modern powder coating lines, the finish on our screws is exceptionally durable and resistant to mechanical damage. The polyester powder, cured at high temperatures, provides an additional protective barrier against corrosion.

Moreover, coatings are available in a variety of colors, allowing for an aesthetic match with roofing materials and customer preferences, while maintaining high quality and resistance to external factors.

Screws that are hand-painted or coated using traditional “wet” methods do not provide adequate coating quality — the finish may peel or become damaged during installation. That’s why all fasteners we supply are exclusively coated in-house, ensuring consistent performance and appearance.

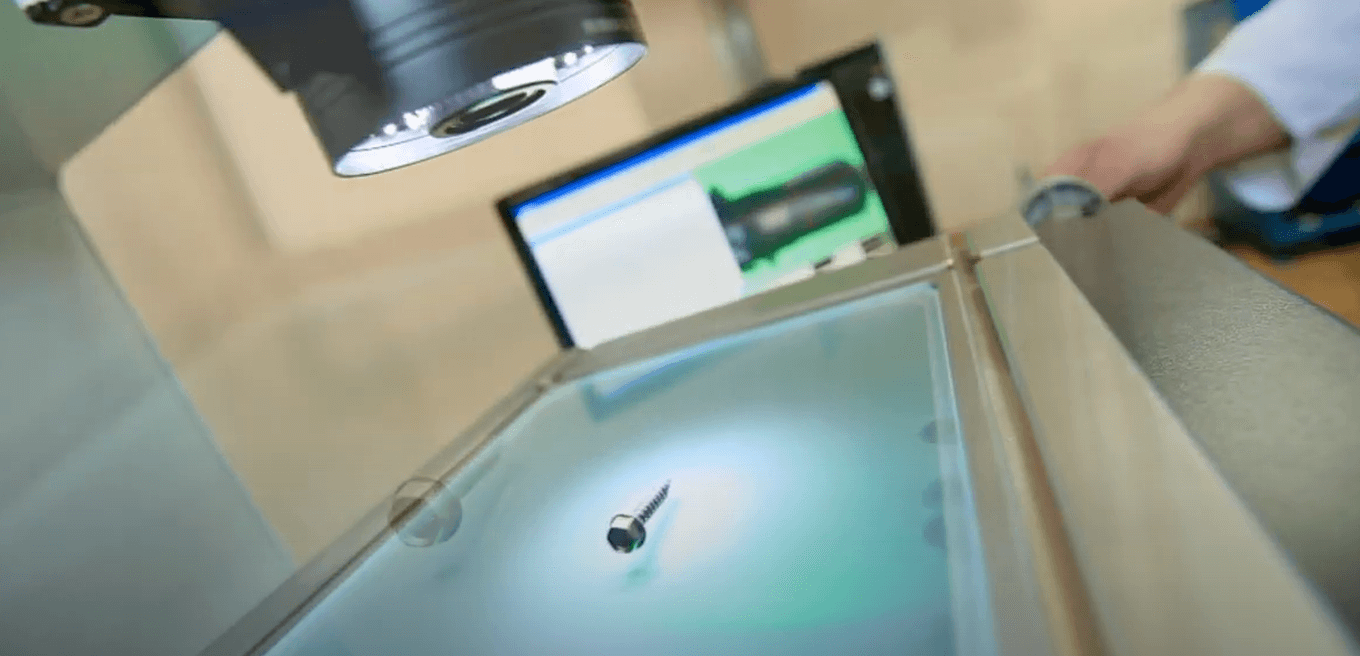

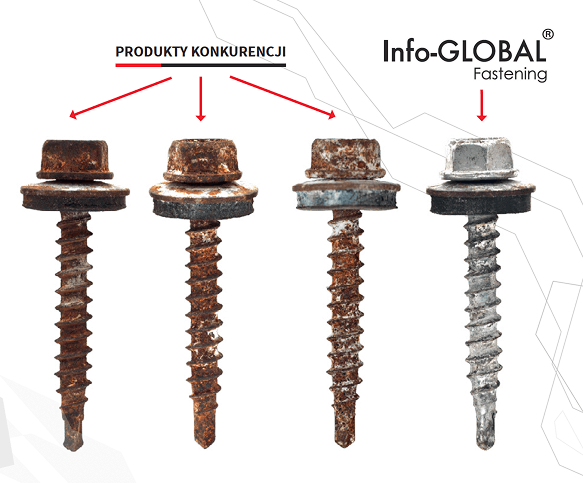

Screws tested in accordance with PN-EN ISO 9227:2007 – after 144 hours in a salt spray chamber

Corrosion resistance of screws

Coatings with a thickness of 12 or 24 microns offer an optimal balance between corrosion protection and high mechanical durability. They are successfully used in construction and metalworking industries.

The most common coating is 12 microns thick, providing reliable corrosion resistance by protecting screws from rust and degradation, which extends their service life. This protection ensures that screws retain their performance properties, offering stable fastening of metal sheets and structures over time.

Additionally, high-quality coatings improve resistance to salt, chemicals, and other aggressive substances often present in industrial or outdoor environments.

Corrosivity classification table

| Corrosivity category according to PN-EN ISO 12944-2 | Examples of temperate climate environments (for information purposes only) | ||

|---|---|---|---|

| Outside | Inside | ||

| C1 | Very low | N/A | Heated buildings with clean atmosphere, eg. offices, shops, schools, hotels |

| C2 | Low | Atmospheres polluted to a small extent mainly rural areas. | Unheated buildings, in which condensation may occur, eg. warehouses, sports halls. |

| C3 | Average | Urban and industrial atmospheres, average dioxide pollution sulphur (IV). Coastal areas with low salinity. | Production rooms with high humidity and some pollution of air, eg. food processing plants, laundries, breweries, dairies. |

| C4 | High | Industrial areas and coasteel areas with medium salinity. | Chemical plants, swimming pools, repair shipyards of ships and boats. |

| C5-I | Very high (industrial) | Industrial areas with high humidity and aggressive atmosphere. | Structures or areas with almost permanent condensation and high pollution. |

| C5-M | Very high (marine) | Coasteel areas and away from shore into the sea with a large salinity. | Structures or areas with almost permanent condensation and high pollution. |

Got questions or interested in working together?